Tesla structural repair for floor pans and rocker sections is crucial for passenger safety and vehicle value. Common issues include dents, bends, or separation caused by accidents or road debris. The meticulous repair process involves thorough inspection, disassembly, precise measurement, and fitting replacement parts. Skilled technicians use welding, riveting, or bonding to ensure alignment and structural integrity. Quality checks confirm compliance with high standards. Best practices for longevity include using high-quality certified parts, proper alignment, regular maintenance inspections, and promptly addressing issues. Specialized Tesla repair services from reputable auto body shops leverage advanced tools and techniques for reliable restoration.

Tesla vehicles are renowned for their innovative design, but like any car, they require meticulous maintenance. One crucial aspect is understanding and addressing structural repairs, particularly for floor pans and rocker sections. These components play a vital role in vehicle stability and safety. This article delves into the intricacies of Tesla structural repair for these essential areas. We explore common damage patterns, provide a step-by-step guide to the repair process, and offer tips to ensure longevity.

- Understanding Tesla Floor Pan and Rocker Sections: Their Role and Common Damage Patterns

- The Process of Tesla Structural Repair for Floor Pans and Rocker Sections: Step-by-Step Guide

- Tips and Best Practices for Ensuring Longevity After Tesla Structural Repair

Understanding Tesla Floor Pan and Rocker Sections: Their Role and Common Damage Patterns

The floor pan and rocker sections are vital components of any Tesla vehicle’s structure, acting as a protective cage around the passenger compartment. These panels are designed to crumple in a collision, absorbing impact energy and preventing severe damage to the cabin. Understanding their role is crucial when it comes to effective Tesla structural repair. Common issues often arise from accidents or road debris, resulting in dents, bends, or even complete separation of these sections.

Rocker sections, located along the car’s sides, are particularly susceptible to damage during side impacts. Floor pans, on the other hand, can suffer from various patterns of distortion, including warping or punctures. Prompt recognition of these damage types is essential in the auto detailing and collision repair process, as it dictates the methods used for Tesla structural repair. Efficient repairs ensure not just the safety of future occupants but also maintain the overall integrity and value of the vehicle, avoiding the need for excessive auto glass repair or other costly components replacements.

The Process of Tesla Structural Repair for Floor Pans and Rocker Sections: Step-by-Step Guide

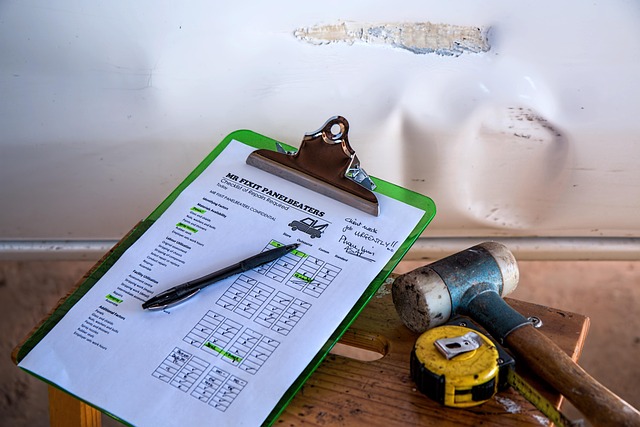

Tesla structural repair for floor pans and rocker sections involves a meticulous process designed to restore the vehicle’s integrity. It begins with a thorough inspection to identify damage, which may include cracks, dents, or deformations. Once the extent of the harm is determined, skilled technicians employ specialized tools and techniques to carefully disassemble affected components, ensuring precise measurement and fitting for replacement parts.

The actual repair entails welding, riveting, or bonding new floor pan and rocker sections into place, adhering to strict manufacturing standards. Throughout this process, collision repair services focus on alignment and structural integrity, guaranteeing the vehicle’s safety and stability. Upon completion, a final quality check confirms compliance with car bodywork services’ high-quality benchmarks, ensuring a flawless restoration.

Tips and Best Practices for Ensuring Longevity After Tesla Structural Repair

After completing Tesla structural repair for floor pans and rocker sections, following best practices ensures longevity and optimal performance. One crucial tip is to use only high-quality parts, certified by Tesla or trusted manufacturers, to maintain the vehicle’s original integrity. Proper alignment during the repair process is paramount; even slight misalignments can compromise structural stability over time.

Regular maintenance inspections are essential, focusing on key areas like welds and joints. Addressing any issues promptly, whether it’s a loose panel or signs of corrosion, prevents minor problems from escalating into major repairs. Many auto body shops offer specialized Tesla repair services, leveraging advanced tools and techniques tailored for electric vehicles, including Mercedes Benz repairs. Just as with meticulous car paint repair, precision is key in structural restoration to ensure the safety and reliability of your Tesla for years to come.

Tesla structural repair, particularly focusing on floor pans and rocker sections, is a specialized process that plays a crucial role in ensuring vehicle safety and longevity. By understanding the common damage patterns and implementing the step-by-step guide provided, owners can effectively address these issues. Following best practices for aftercare guarantees that the repairs stand the test of time, keeping your Tesla safe and reliable on the road. For those seeking expert knowledge, this comprehensive guide offers a valuable resource for maintaining your vehicle’s structural integrity.